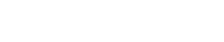

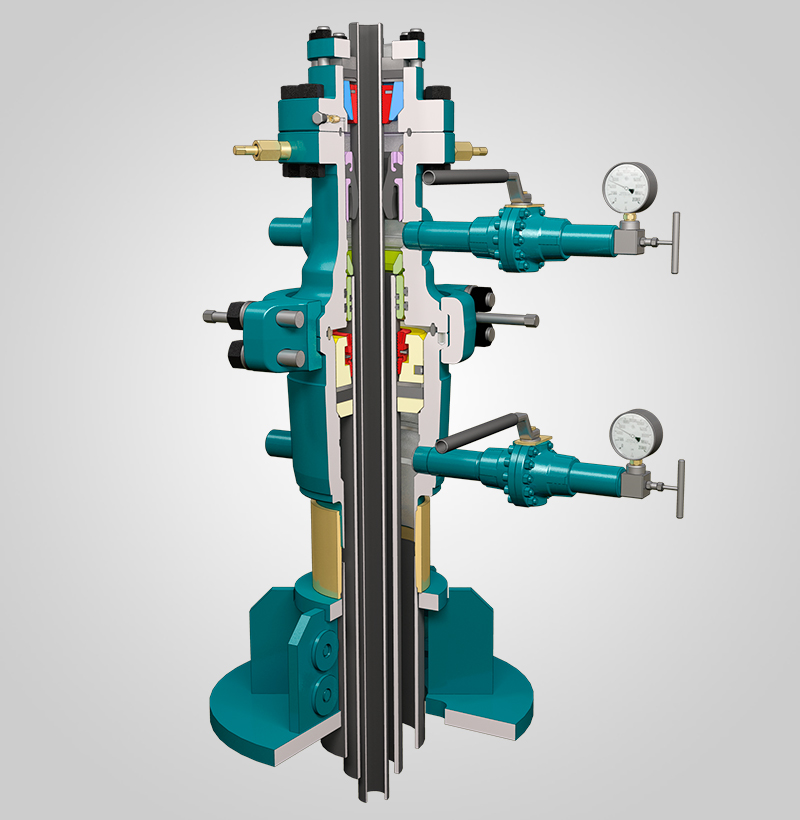

RTO Conventional Wellheads

The RTO wellhead reduces operating time and increases safety.

It is provided with an API clamp connection. It is applicable to completions with 10-3 / 4 "or 9-5 / 8" surface casing and 5 ", 5-1 / 2" and 7 "production casing.

It is available for pressures of up to 5,000 psi.

It is provided with an API clamp connection. It is applicable to completions with 10-3 / 4 "or 9-5 / 8" surface casing and 5 ", 5-1 / 2" and 7 "production casing.

It is available for pressures of up to 5,000 psi.

- The head is connected to the casing on the rig floor. Faster and safer.

- It is lowered through the 17” rotary table.

- The BOP is installed by means of a clamp-connector.

- The tubing spool is installed with a clamp connector.

- The retrievable base eliminates waiting time for the cement to set in the 9-5/8” casing.

- The Mandrel Hanger eliminates cutting, bevelling, and waiting time for the cement to set in the 7” casing.

Conventional Wellhead Procedure

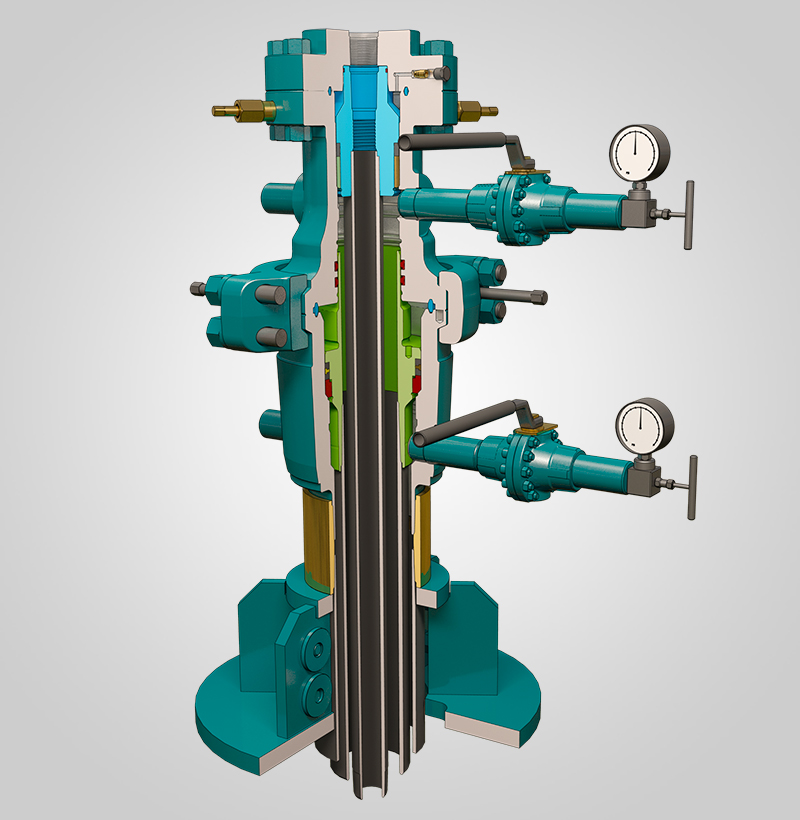

RTO Mandrell Wellhead Procedure

RTO-3 Wellhead

RTO-3 wellhead saves operating time and increases safety. It´s has a fast connector for BOP and production wellhead installation. It is suited for 10-3/4” or 9-5/8” surface casing and 5”, 5-1/2” or 7” production casing completions. Available for pressures up to 5,000 psi.

- It is connected to the surface casing at rig substructure and lowered through the rotary table.

- Lower male thread avoids for last casing section coupling to be removed.

- Landing base eliminates the cement hardening waiting time.

- Double pressure barrier.

- Casing hanger with flow channels for fluid circulation.

- Packoff lowered through BOP and retained by snap ring.