Moto Mecánica Argentina S.A.

Research and Development

We have our own technology to offer innovative solutions, products in constant technological evolution and cooperation from the beginning phases of the project.

Engineering and Development department has ample resources, such as:

-

Human resources with extensive experience and a high degree of training.

-

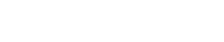

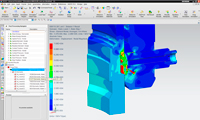

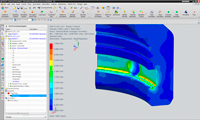

Advanced tools for designing, calculating, simulating, and managing information, CAD / CAM / FEA / IT.

-

A modern performance-testing laboratory that allows testing prototypes under extreme design conditions.

-

A non-metallic-seal testing laboratory for thermochemical testing.

The engineering staff is in direct contact with the client for counseling, establishing work groups, and troubleshooting.

Installation, Operation and Maintenance Manuals are prepared with instructions and drawings to help assist the user in the field.

Training courses are provided and technical meetings are held at our plant, and at our bases or oilfields, upon client’s request.

Tools for design, calculation, simulation and management of the information

Performance testing laboratory

The purpose of this laboratory is to subject prototypes to extreme service conditions, in order to verify that the suitability of the design satisfies the demands of applicable standards.

These tests allow the product to be certified for the specified service in accordance with Appendix F of API 6A, level PR2, awarding the product the degree of reliability required to offer it on the domestic and foreign markets.

Thermochemical compatibility testing laboratory for non-metallic seals

This testing laboratory is a key facility to ensure the reliability of non-metallic seals subjected to the conditions of pressure, temperature and chemical action of standard test fluids according to API 6A, Appendix F.