MC Casing Heads

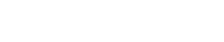

The bottom connection can be either threaded, prepared for welding , or supplied with a slip-lock quick-connector.

Also available are type MC-22P and MC-29P casing heads manufactured with two tie-down screws to secure the wear bushing. These do not accept MC-21 hangers with type H seal rings.

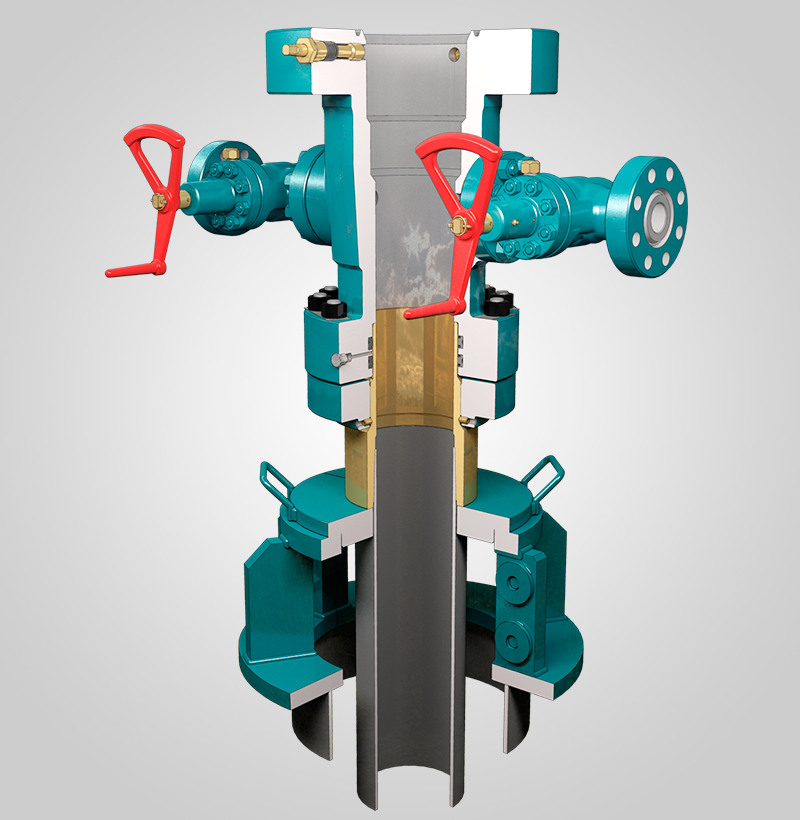

Landing Base

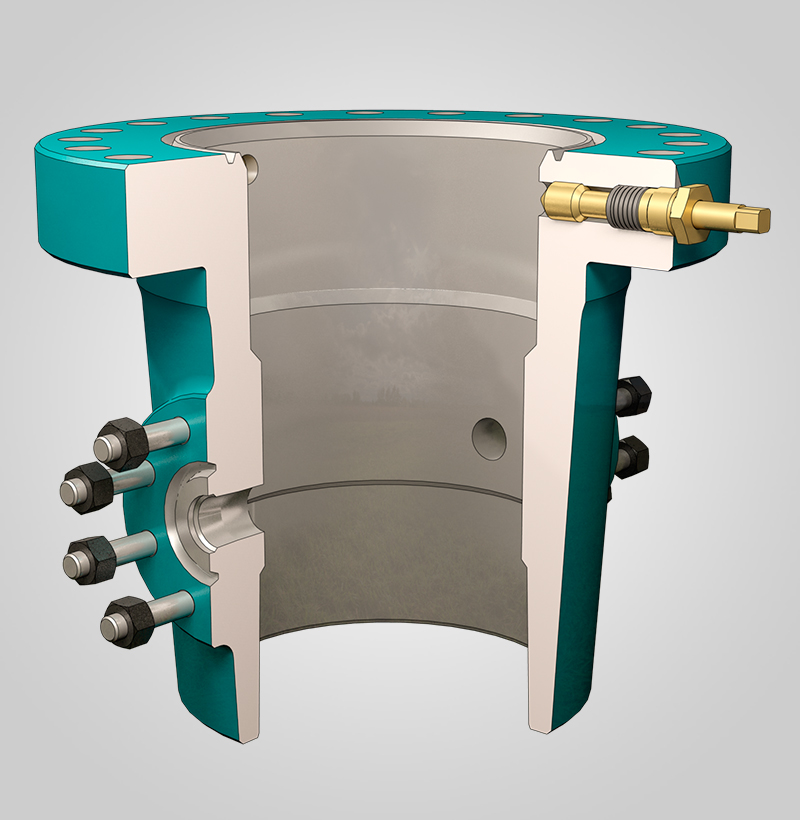

Casing Heads with a Slip-Lock Quick-Connector

The casing head with a slip-lock quick connector may replace the traditional threaded or welded connections.

The slip-lock eliminates the loss of time produced when the casing or the head thread is damaged, which may occur when the connection has a large diameter.

It may also be used in a contingency case when that occurs. It saves rig time when it replaces a welded connection. The slip-lock has a set of slips to anchor the head to the surface casing, and a type S or P dual seal. The slips are activated by tightening the bolts.

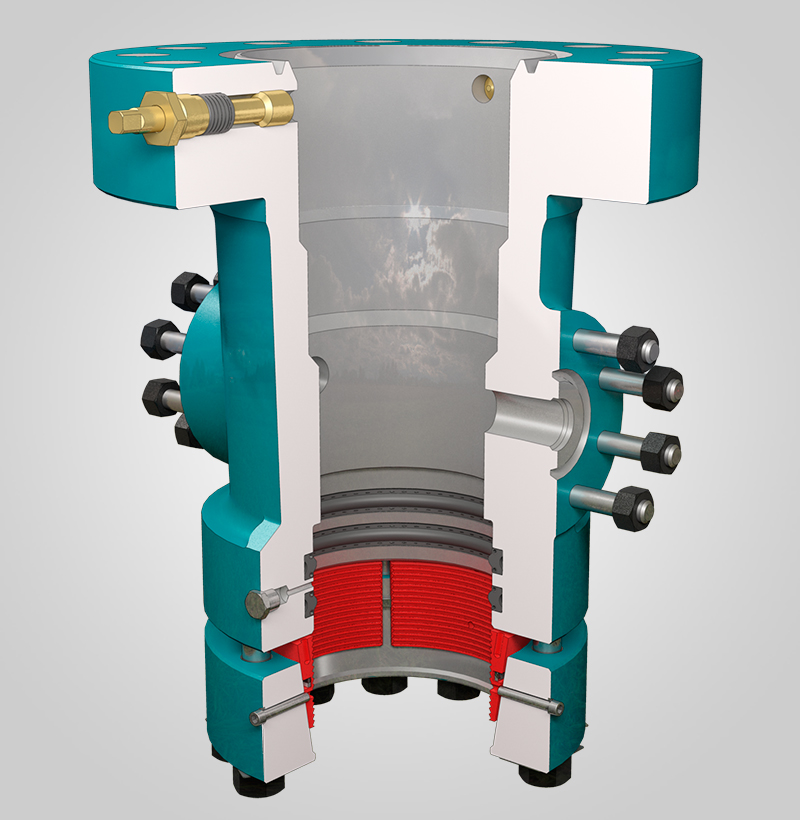

Casing Heads with Landing Hanger Connection

They are a convenient alternative to eliminate the waiting time incurred in the cement hardness at the casing Guide. Casing Head and BOP can be installed immediately after the cementing operation.

It´s conformed by three parts:

- A supporting base that can be fixed or removable that distributes the weight on the pit´s floor.

- The body is threaded at the end of the pipeline, it has an extended neck from which the energizable package seal in the wellhead is acted.

- A bonding flange keeping the head attached to the Landing Hanger.