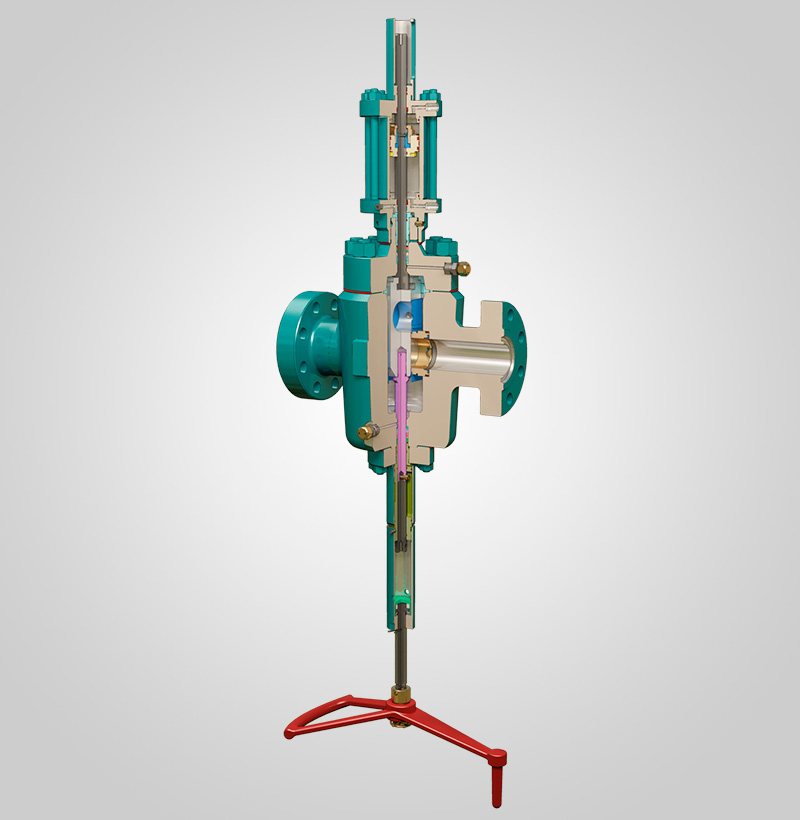

Frac valves characteristics design and materials are suitable to work in this severe service. They are supplied for manual operation or operated with hydraulic actuator.

The manually controlled valves of 4-1/16" and larger have balanced stem and an actuator system mounted on ball screw mechanisms. This feature allows ease of operation of valve with a reduced number of turns therefore reducing time the valve is not fully open or closed position. This features allows to preserve the integrity of internal components (specially gates and seats). These valves can be manufactured as loose valves or in the solid block stile.

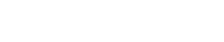

Model HDA Surface Safety Frac Valve

In case of not having an hydraulic pressure source, the valve has a manual override system handwheel with recirculating balls in order to open or close the valve with no excessive torque needed.

Gate Valve Model T15AF & T10AF

Bidirectional Sealing:

Metal to Metal Seal:

Sealing at gate-to-seat and seat-to-body is metal to metal.

Stem Packing:

No body Penetrations:

Easy Operation:

Back Seating:

Field Replaceable Seats:

Floating seats are easily field replaceable.

Stem:

Actuator Valves:

Model AF API 6A gate valves can be turn into atuated valves with the addition of pneumatic or hydraulic actuators.

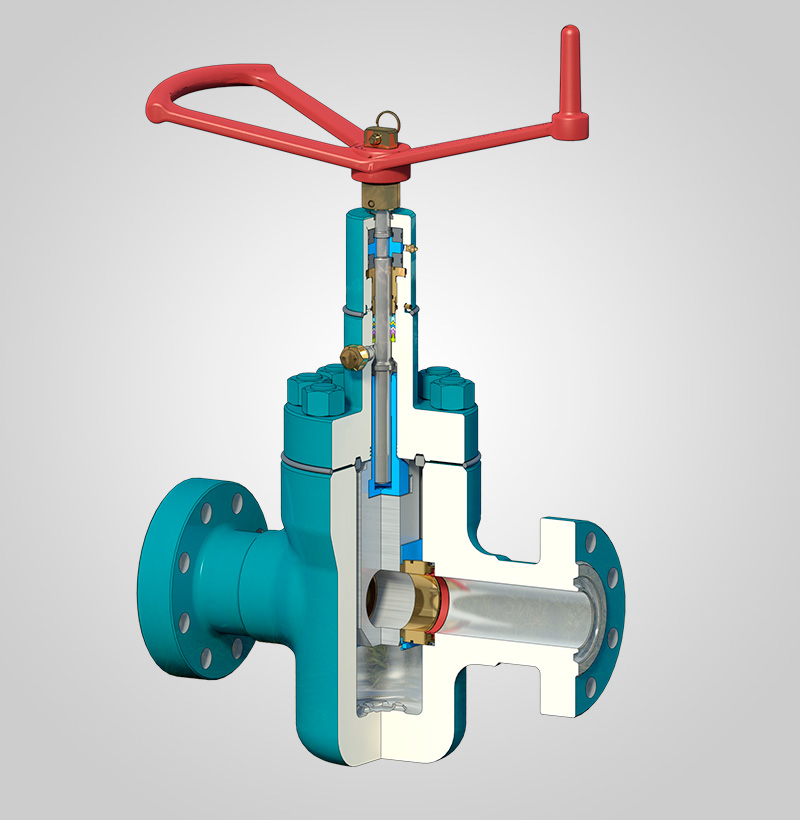

Model T10BR & T15BR Gate Valve

The models T10BR & T15BR API 6A gate valves has a balanced stem and recirculating balls. It has been developed to manually operate large-diameter and high-pressure valves.

It is used to serve as a on-off valve in oil and gas services up to 15,000 PSI.

It is manufactured in sizes from 4-1/16" to 9". It is suitable for use in production trees, conduction systems and fracture trees.

It is suitable for use in production trees, conduction systems and fracture trees.

Metal to Metal Seal:

Bidirectional Sealing:

Stem Packing:

Body without Penetrations:

Easy Operation:

The valve opens and closes without needing excessive torque. The screw-and-nut actuating system with recirculating balls is of high performance, allowing for the valve to be operated directly, without the need of a gear reducer. This system minimizes the number of handwheel turns for operation. After the necessary number of turns required for closing the valve, the handwheel must be backed off ¼ turn.

Stem Shear Pin:

Replaceable Seats:

The floating seats can be readily replaced in the field.