Simple Completation Tubing Hangers

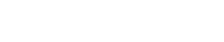

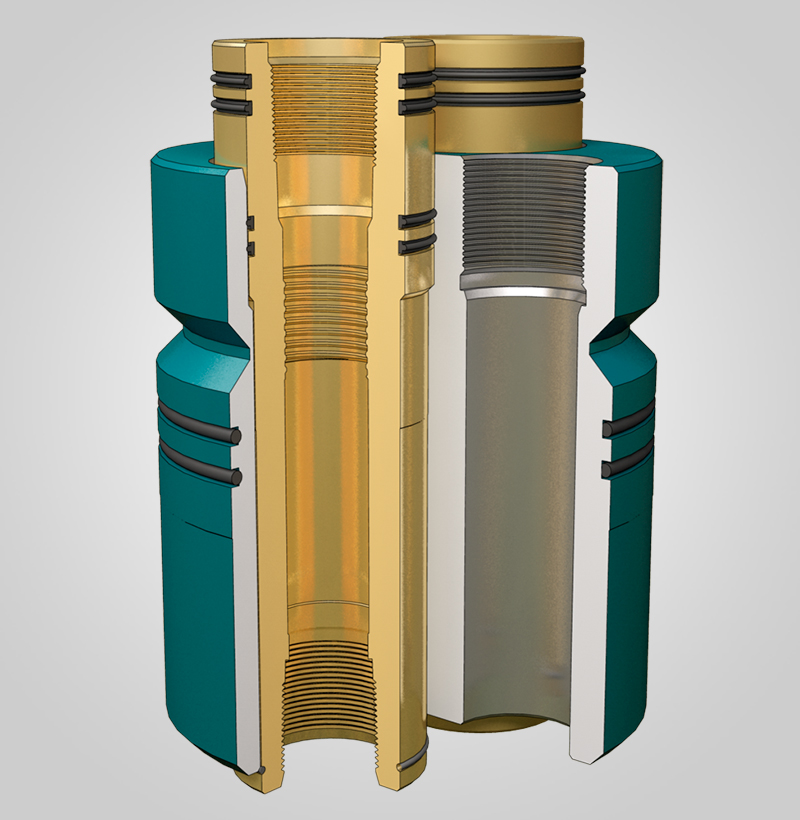

Type MC1 and MC2

They are furnished with preparation for a type H back-pressure valve (BPV) and are housed in the MCM and TFF-FC tubing spools.

MC2 hangers are similar to MC1, except they feature a preparation for a control line.

Type MCP1

They feature an extended neck that provides a secondary seal to allow the primary seal and the flanged connection to be tested.

They are housed in the MCM and TFF-FC spools. They are furnished with preparation for a type H back-pressure valve (BPV).

Type MC-1A

They are housed in the MCM and TFF-FC spools.

Type MC-1A-BP

Type DHA

They are furnished with preparation for a type H back-pressure valve (BPV). The primary seal is energized by the weight of the tubing.

Type MC-1W

The annular seal is energized by tightening the the tie down screws of the tubing spool. They are housed in the MCM and TFF-FC spools.

Type MC1-MS and MC2-MS-LC

They are suitable for working with premium thread tubing having connections with a metal-metal seal.

Type MC1-DMS and MC2-DMS-LC

They have a metal-metal seal on the extended neck that makes them suitable for working with premium thread tubing that have metal-metal seal connections.

They also incorporate a metal-metal primary seal activated by the tie down screws of the tubing spool, and a backup elastomeric seal.

They are furnished with a preparation for a type H back-pressure valve (BPV) and are housed in the MCM and TFF-FC spools. MC2-DMS-LC hangers are similar to the MC1-DMS, except they have a preparation for a continuous control line and a monitoring line if required.

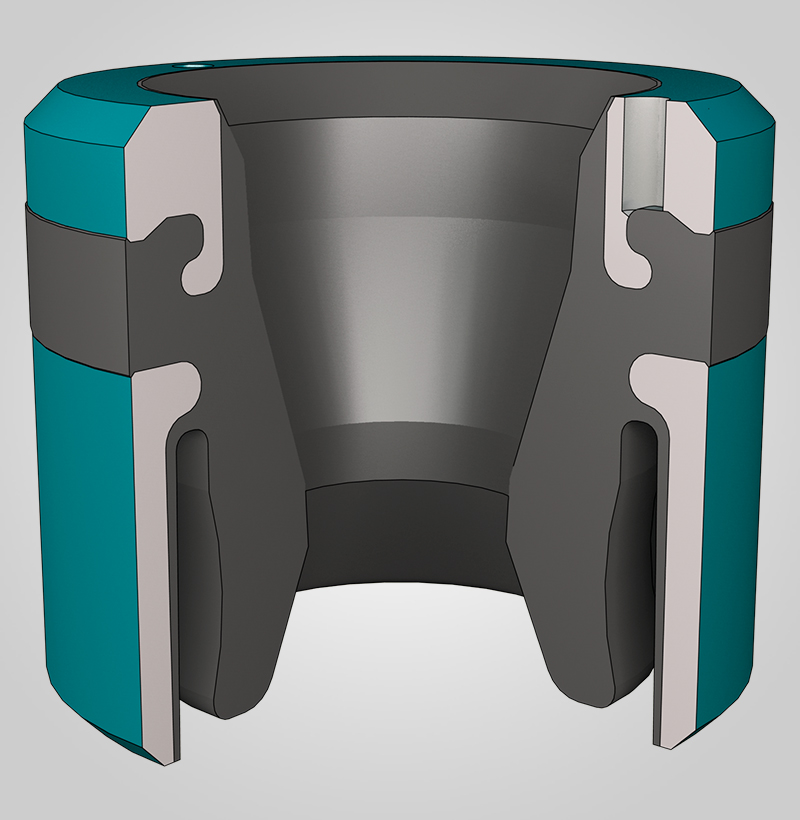

Model MCS Stripper

The model MCS stripper provides an annulus seal that allows safely handling the tubing and it is designed for 3,000 psi maximum working pressure.

It is installed in the model MCM production spools and must be used together with the model CUBP independent wellhead to hang the tubing.

Dual Tubing Hangers

MC-2BES Tubing Hangers

They are designed to lower two strings of tubing simultaneously and receive two mini-mandrel type electrical connectors. They consist of a hanger body in which the two hanger nipples and the two electrical connectors are housed. Each nipple has an upper female thread for maneuvering, and a bottom female thread for hanging the tubing, both usually of the API EU type (other types of threads may be made upon request).

On its inner half they have a special female thread to attach a type H back-pressure valve (BPV). As the hangers are inserted into the tubing spool, they set themselves on the head’s conical seat due to the weight of the hanged tubing string. The annular seal is obtained by means of two O-rings, and the seal between the hanger nipples and the adapter flange is obtained by means of two pairs of type "S" seals.

MC-2C Dual Tubing Hangers

They are designed to lower the two tubing strings simultaneously. Each nipple has an upper female thread for maneuvering, and a bottom female thread for hanging the tubing. The nipples have an extended neck to isolate the well pressure and allow the flanged connection to be tested.

Both nipples are threaded for a type H back-pressure valve (BPV).

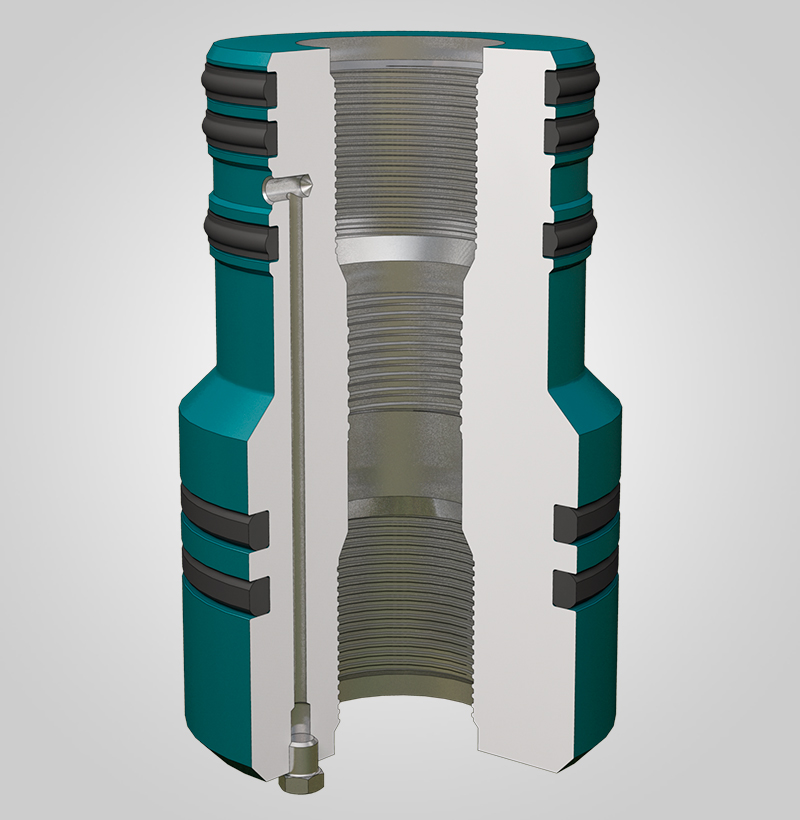

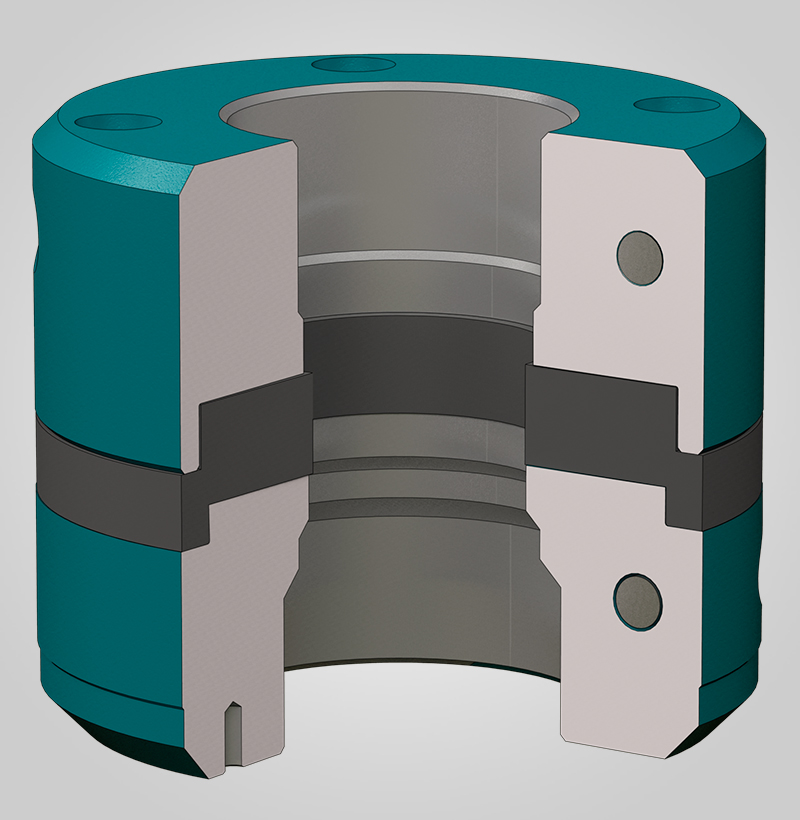

MC-60 Dual Tubing Hangers

The MC-60 dual tubing hangers are housed in the MC-60 tubing spools. They are of the split type and allow the strings of tubing to be lowered independently.

The annulus seal is actuated by tightening the tie down screws of the tubing spool . It has two subs at the top to isolate the well pressure and allow the testing of the flanged connection.

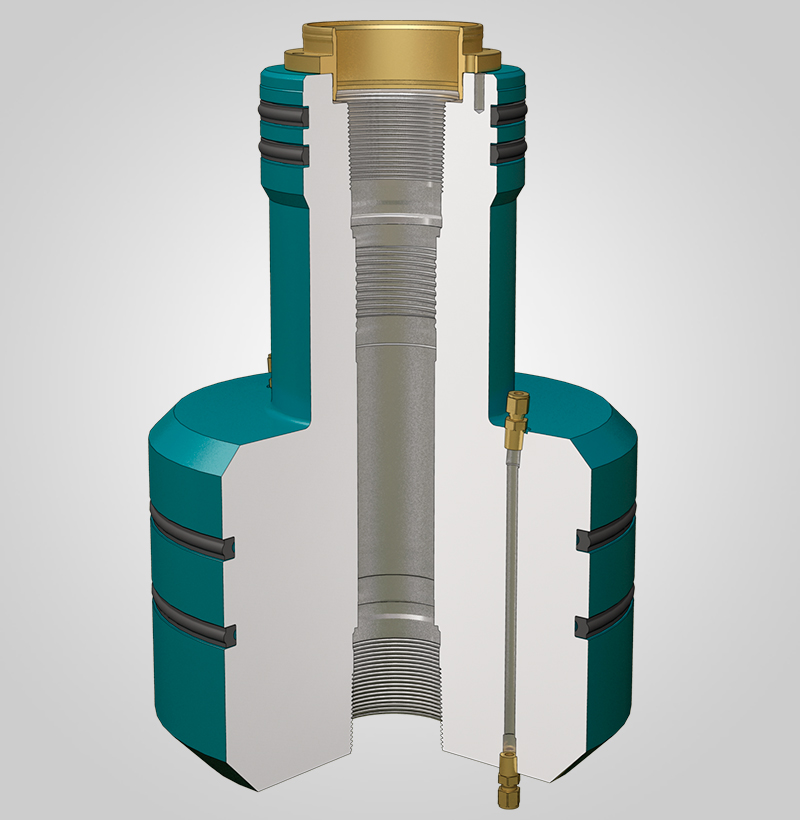

Tension Hanger

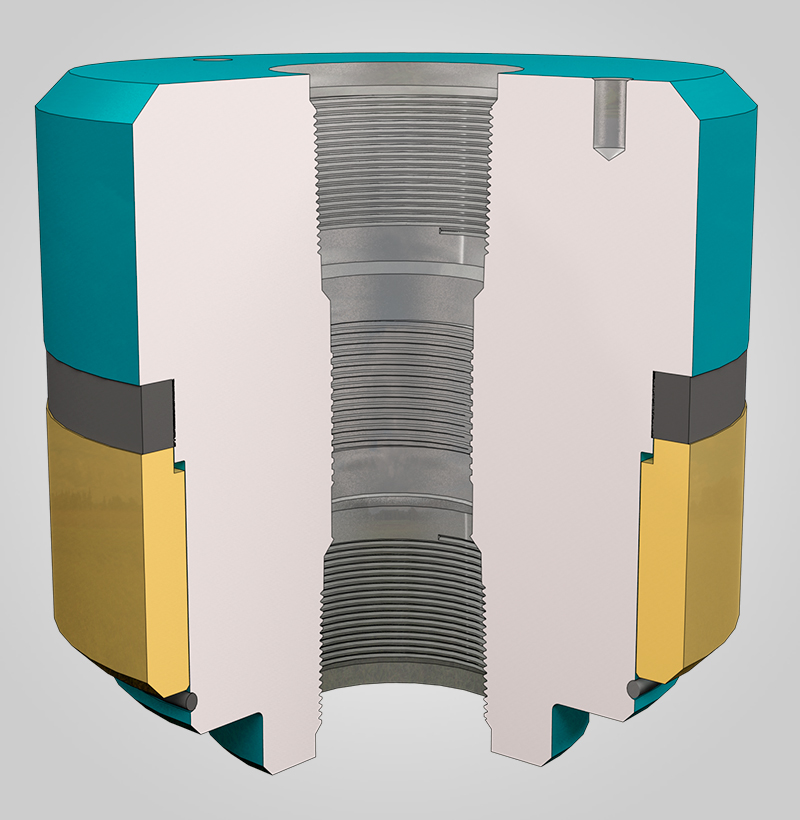

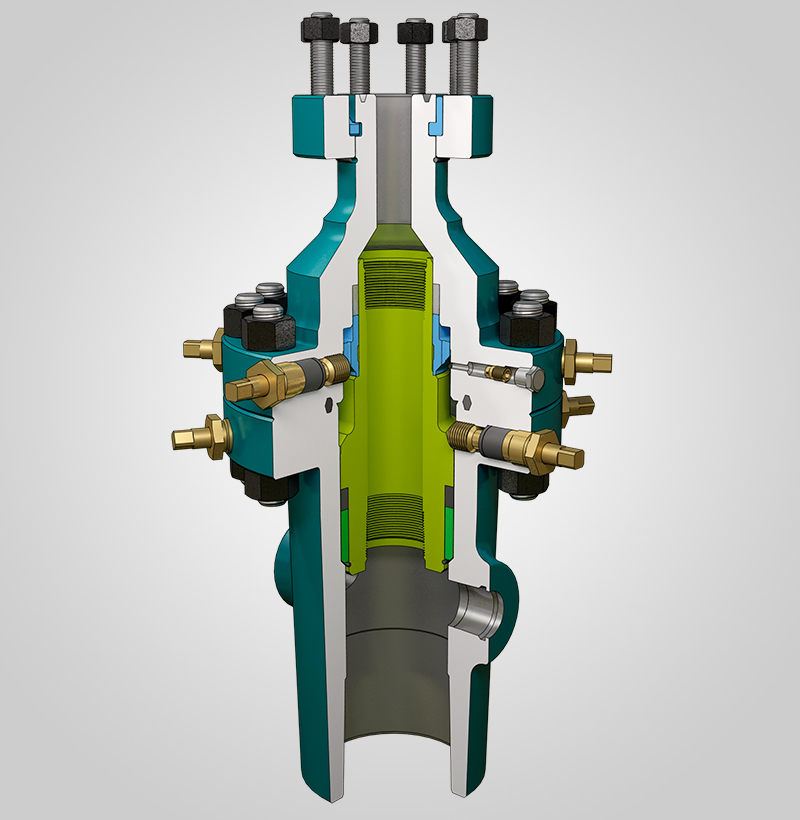

Type MC1-T Tubing Hanger

- The MC1-T tubing hanger allows the tensioning of the tubing string in order to house the pump anchor or tension packer. It has two shear pins that allow the body-packer assembly to be lowered.

- Four load screws withstand the weight of the string initially, maximum load 110,000 lbs, then the load nut can withstand the entire weight permanently, even if the load screws are released.

- The MC1-T tubing hanger is installed on a MCM-T tubing spool with preparation suited to the corresponding diameter of the casing, and allows the BOP to be removed safely (Packer and BPV installed).

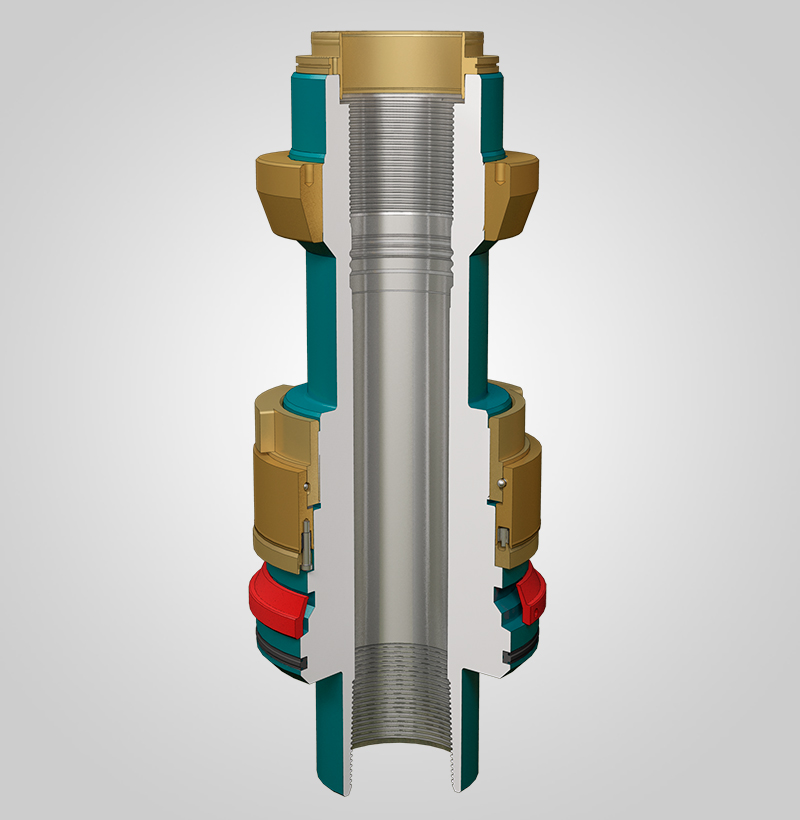

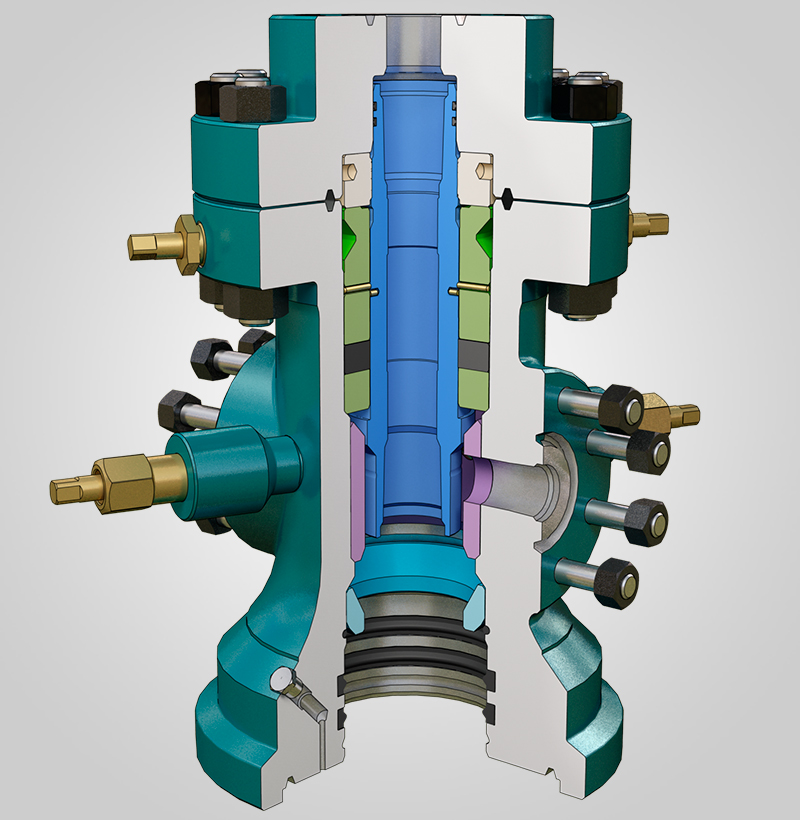

Type MC-CTJ Tubing Hanger

- The type MC-CTJ tubing hanger allows the tensioning of the tubing string in order to house the pump anchor or tension packer without BOP removal.

- This hanger doesn´t require special casing spools and tools as it can be installed in any MMA´s type MCM 7-1/16” 3,000/5,000 PSI standard casing spool .

- Hanger´s Type “J” system facilitates installation and reduces operating time.

- The packer´s loading pins withstand up to 85,000 lbs.

Tubing Hangers for Steam Injection

Model MIV-E1 Tubing Hanger

The standard versions of this hanger are manufactured in carbon steel as well as in stainless steel. It has an extended neck to form a secondary seal that isolates the annular space and allows for testing of the flanged union.

This hanger has a top female thread for maneuvering, and a bottom female thread for hanging the tubing , both usually of the API-EU type (other types of threads may be made upon request).

Tubing Hangers for Electrical Sumersible Pumping

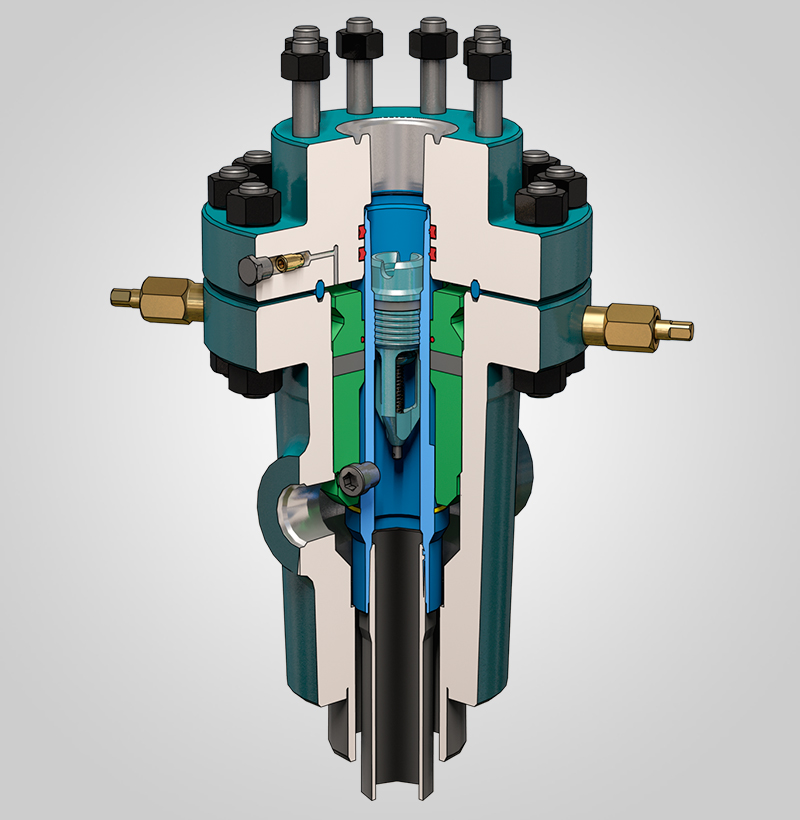

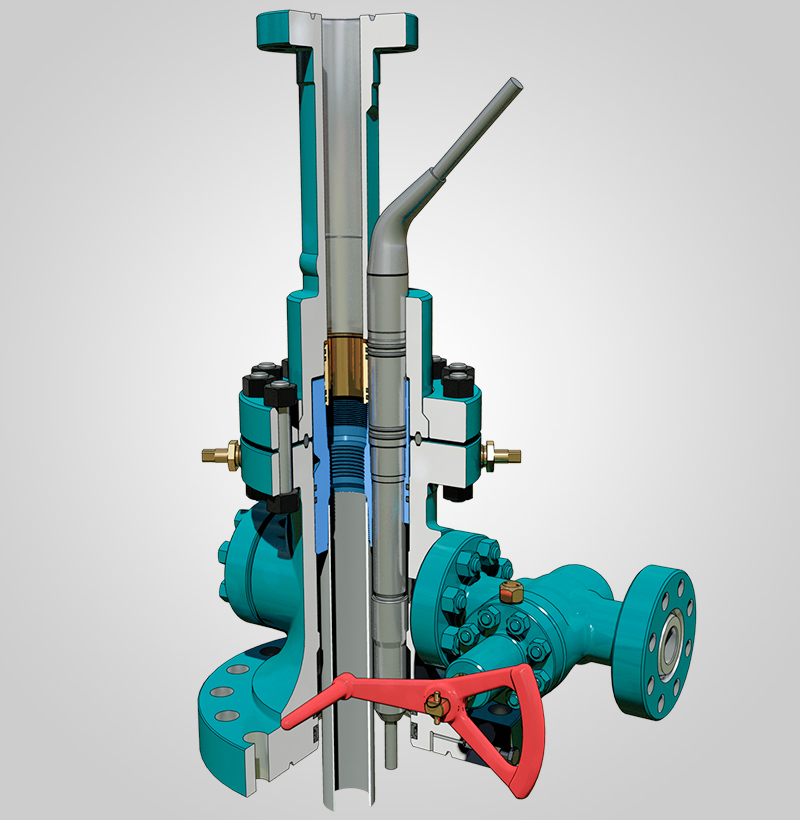

MC-BES Tubing Hanger

The MC-BES tubing hanger is housed in a type TFF-FC tubing spool. It is furnished with a seal that isolates the well pressure and allows for testing the flange connection. They have internal threads to house the back-pressure valve (BPV).

They are manufactured with adequate preparation to house the specified electrical connector.

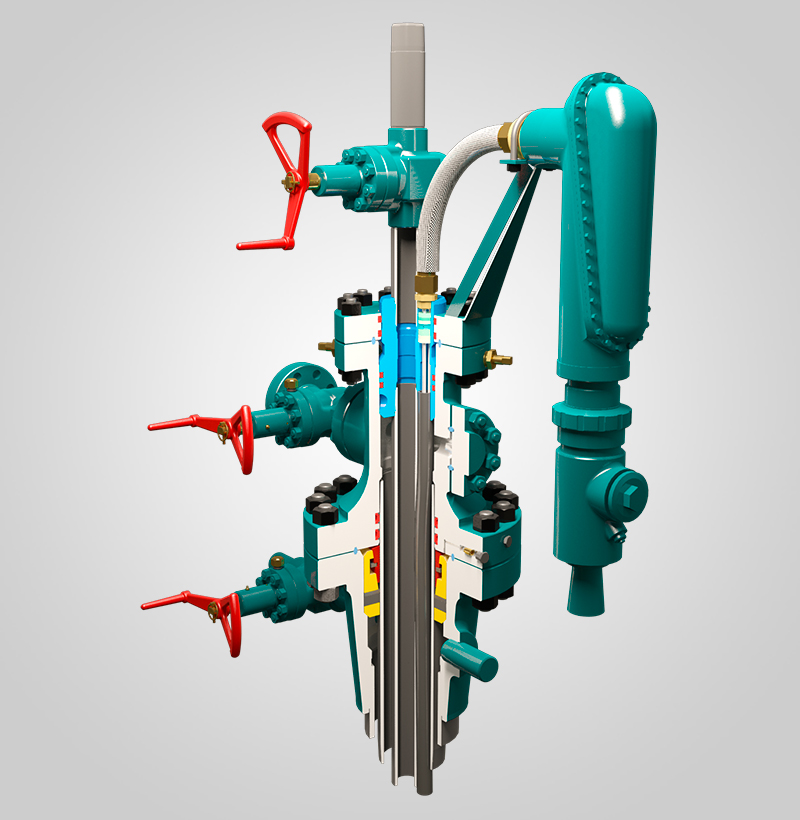

MC-BES-SP Tubing Hanger

The MC-BES-SP tubing hanger is intended up to 3,000 psi, and is housed in MCM tubing spools. It allows the three power cables to pass through the tubing hanger and packing them with a double seal.

It is furnished with a housing for a back-pressure valve. It includes an explosion-proof installation assembly consisting of a hanger, an adapter flange, a hose, a bracket, a junction box, and an electrical sealant.